Researchers from QUT have partnered with solar cell manufacturers in a project that aims to commercialise ultra-low cost, flexible perovskite solar cells.

QUT has partnered with two Australian companies working in solar research and development on the project to produce perovskite solar cells that are significantly cheaper than traditional solar cells with comparable efficiency.

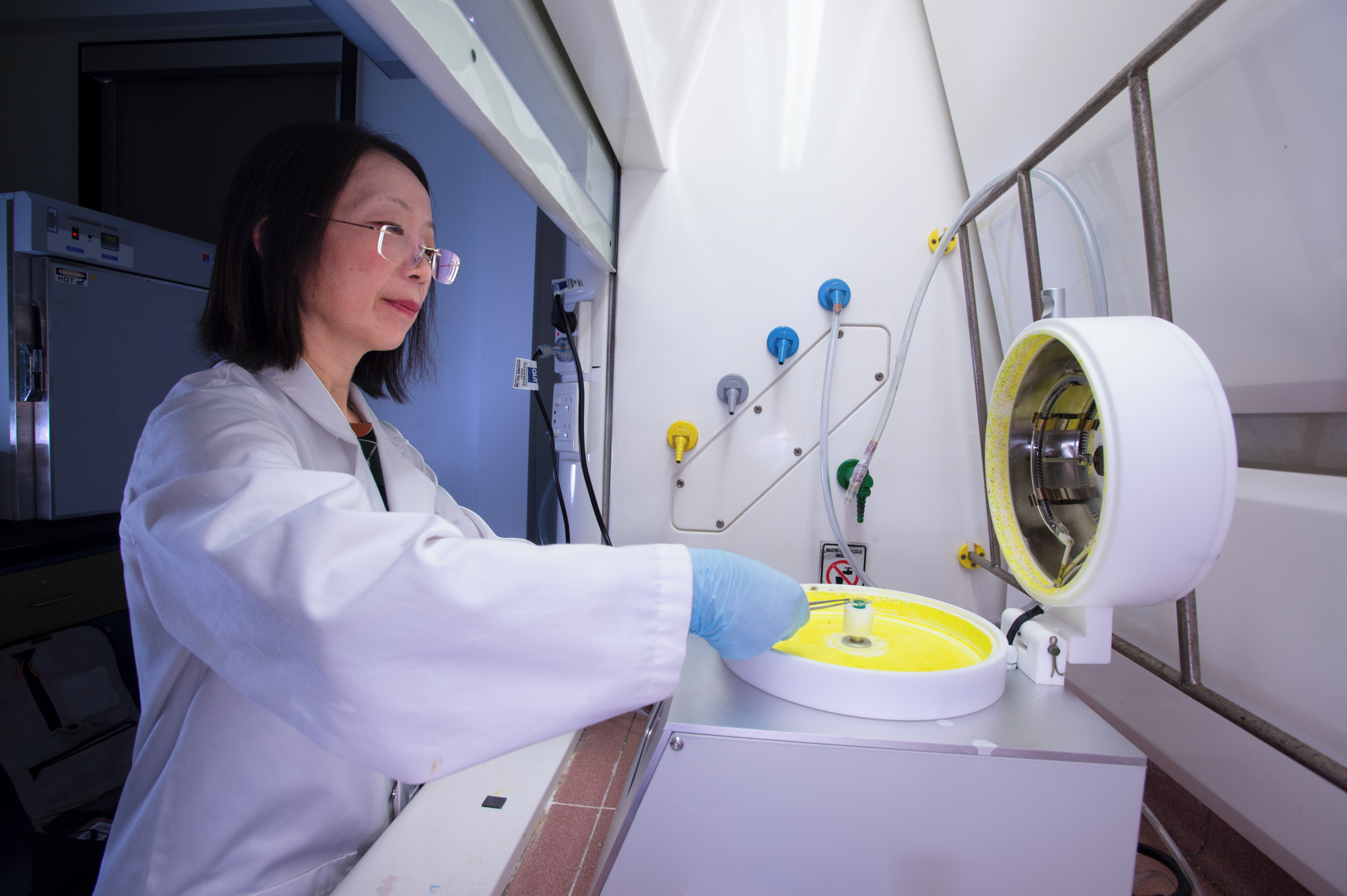

The lead investigator on the team Professor Hongxia Wang from the QUT School of Chemistry and Physics and the QUT Centre for Materials Science said a consortium led by Halocell Energy, including First Graphene and QUT, was awarded a grant of $2,028,773 from the Australian government’s Cooperative Research Centres Project, or CRC-P initiative.

“QUT will deliver expertise in material development, facilities for advanced material characterisation and testing, and assistance in developing carbon inks using low-cost carbon materials and graphene in collaboration with Halocell and First Graphene for roll-to-roll production of perovskite cells and modules,” Professor Wang said.

“It’s a three-year project with a total funding size of more than $5.26 million,” Professor Wang said.

Professor Wang said the key project outcomes were likely to include replacement of high-cost precious metal-based conductor materials with cost-effective carbon-based composite materials and up-scaling the production process to allow high volume, ultra-low-cost production of the perovskite solar cells.

“This will facilitate the commercialisation of perovskite photovoltaics in Australia using all Australian raw materials, improving energy security and providing significant job opportunities as a primary and enabling technology for other small to medium-sized enterprises,” Professor Wang said.

The project is led by Halocell CEO Paul Moonie (Halocell), and the team includes Dr Minh Tam Hoang, a Postdoctoral Fellow from the QUT School of Chemistry and Physics; Dr David Pham (Chief Science Officer, Halocell), and Dr Ian Martin (R&D Manager, First Graphene).

The perovskite solar cells will be manufactured using Halocell’s roll-to-roll production process at the company’s Wagga Wagga plant, in southern New South Wales.

Solar cell efficiency is the measure of how much sunlight a solar cell can convert into electricity.

Mr Moonie said perovskites solar cells offered many advantages over traditional silicon solar cells.

Silicon cells have reached the peak of their technical innovation but perovskites solar cells have already demonstrated their efficiency of more than 26 per cent within ten years of research and development.

Mr Moonie said among the advantages of perovskite solar cells is that they could be applied on flexible substrate using low cost roll-to-roll production processes.

“And perovskite cells are quite simply better for the planet with a significantly smaller manufacturing footprint, far less energy intensive with much less toxic waste material than existing photovoltaics technology.”

Graphene is a one-atom-thick layer of carbon atoms arranged in a hexagonal lattice. It is the building block of graphite, which is used, among other things, in pencil tips.

Michael Bell, managing director and CEO of First Graphene, said previous research had found that cells made with alternative carbon-based materials outperform conventional silicon cells in low and artificial light conditions, including indoor environments in relation to generating and supplying power for niche applications.

“Validation of these graphene-based materials will help build a strong business case for full-scale commercial production of both perovskite cells and the materials needed to make them in large volumes,” Mr Bell said.

Media contact:

Pat Whyte, QUT Media, 07 3138 1150, media@qut.edu.au

After hours: 0407 585 901