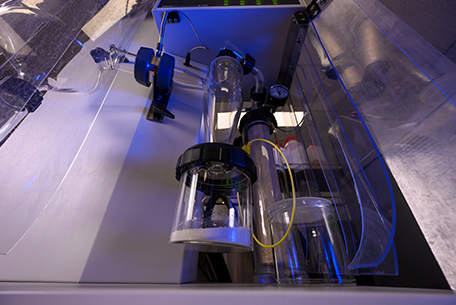

The Fermentation and Bioprocessing Laboratory supports researchers, students and project partners to undertake laboratory bioprocess development with a focus on cutting-edge equipment and expertise in precision fermentation and downstream processing. Laboratory bioprocess development is a key step prior to moving to pilot scale (e.g. MRBPP) then onto demonstration and commercial activities.

We also collaborate with QUT's Faculty of Science to train students and researchers in the use of our equipment and further develop the future of the Australian bioeconomy.

Our laboratory has PC2 certification (BC2 upon request).

Supported by the Bioinnovation Research Facility, our laboratory enables researchers and collaborators to identify the best ways of finding answers to their bioprocessing research questions. We also collaborate with QUT’s Faculty of Science to train undergraduate students in the use of our equipment and further develop the future of the Australian bioeconomy.

Research

We have enabled real world results for a diverse range of multi-scale research projects.

- Microbial protein production systems – strain discovery, development and fermentation (bacteria and yeast).

- Probiotic animal feed supplement development and testing.

- Food waste processing to extract high-value nutraceuticals.

- Microbial oil production from sugarcane bagasse.

- Microbial fuel cells.

- Textile waste treatment for resource recovery.

Our laboratory has PC1 certification (PC2 and BC2 pending).

| Equipment | Features |

|---|---|

Class II Biological Safety Cabinets | This ventilated laboratory workspace enables a safe space for working with materials contaminated with pathogens requiring a defined biosafety level. |

Tempered or cool static or shaker incubator | We have access to various temperature-controlled cabinets. |

Synergy HTX microplate reader | The Synergy HTX microplate reader allows for high throughput screening of strain selection, media selection and small molecules production. |

Anaerobic culture system | This system includes an anaerobic chamber and gas mixing station that permit the successful cultivation of microorganisms on solid and liquid media. |

New Brunswick Bioflo fermenters | These fermenters offer simplicity and ease of use for volumes up to eight litres. |

Gas analysis | Our online/offline mass spectrometers are excellent tools for fermentation monitoring. |

UV-Vis spectrophotometers | These spectrophotometers monitor the growth behaviour of microorganisms. |

Benchtop and Floor centrifuges | Solid-liquid separation and/or concentration. |

Freeze dryer | Condenser refrigeration for freeze drying microorganisms. A useful method for long-term preservation. |

Buchi Spray Dryer B-290 | Spray drying optimisation. |

CF homogenize | An efficient cell disruptor using high pressure to release cellular materials from bacteria, yeast, algae, mammalian and insect cells, fungus and more. |

| Tangential Flow Filtration (TFF) | Cytiva TFF with 8L holding tank supports both HF and cassettes. |

| High Performance Upright Light Microscope | Primo Star with internal HD camera able to examine and analyse microorganisms. Record images and videos with the high resolution of 5 megapixels, compatible to ZEN imaging software. |

Techfors-S bioreactor | Low minimum working volume from 3 to 30 L. In situ sterilisation. Reliable measurement and setting of the bioprocess parameters and communication with eve®. Multiple controlled parameters, such as temperature, stirring speed, pH, pO2, anti-foaming agent, feed. Special options for batch, fed batch and continuous cultivation strategies. |

Our equipment is available to staff, students, external researchers and commercial organisations at a competitive price. Our laboratory provides both self-service and full-service options.

We provide sample preparation and support to suit your individual preference and budget. Our experienced staff can provide training, advice and guidance on the experimental process and the analysis of results, so that you achieve optimal outcomes.

If you’re a QUT staff member or student who wants to undertake research activities with us, follow the steps here.

To arrange a consultation as an external researcher or partner, contact us.

Contact us

Biorefining Research Facility

Room 620, Level 6, Q Block

Gardens Point

2 George St

Brisbane QLD 4000 Australia

Postal address

Biorefining Research Facility

GPO Box 2434

Brisbane QLD 4001