New bone stabilising implant hastens mobility

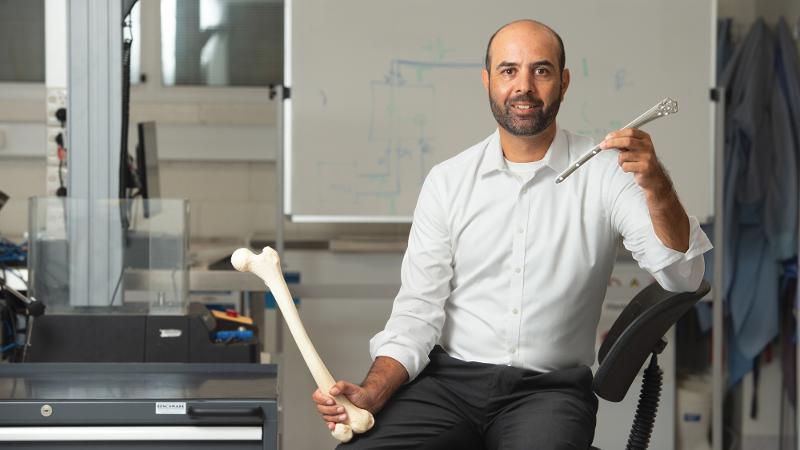

A new implant designed by QUT biomedical engineers to stabilise a long bone fracture above the knee and enable earlier mobility has been used for the first time in an implant operation.

- QUT-designed medical device has received EU’s CE Mark of approval

- New implant device targets difficult to treat long bone fractures

- Biphasic plate allows patients to put weight on their leg sooner

- The new plate is dynamic and balances flexibility with strength

The Biphasic Plate was recently used by a surgeon in Swizterland, after having received European Union approval for medical use last year.

The implant was designed by Associate Professor Devakar Epari and PhD researcher Roshan Gurung from QUT School of Mechanical, Medical and Process Engineering and QUT’s Centre for Biomedical Technologies in collaboration with co-inventor Dr Markus Windolf from the AO Research Institute in Switzerland and Brisbane-based orthopaedic trauma surgeon Professor Michael Schuetz, from QUT School of Clinical Sciences.

The biphasic plate is designed to help repair distal femur fractures which occur on the thigh bone just above the knee.

Biomedical engineer Professor Epari said its design was innovative in that it has a transverse slot in the stainless-steel implant, a dynamic element, that provides both flexibility and strength.

He said the slot in the biphasic plate initially created a low stiffness at low loads and then, when the slot closed at higher loads it became more rigid allowing the person to bear weight on the leg from early on.

“Current plates are either configured flexible and weak or stiff and strong with patients restricted from weight bearing for 10 to 12 weeks,” Professor Epari said.

“Distal femur breaks are one of the most demanding challenges in surgical fracture treatment as they are often complicated, involve a joint and have multiple bone fragments.

“To heal, fractures need a good blood supply and the right mechanical environment.

“If a fixation plate is too rigid, the body doesn’t get the mechanical stimuli needed for it to be ‘aware’ there is a break and to heal the fracture.

“If, however, there is too much motion in the fracture there will be a failure of mineralisation and union of the bone fragments. In extreme cases if the motion persists the body interprets this as a joint and forms cartilage, instead of bone.

“So there has to be a balance between the amount of flexibility to provide motion and strength to allow for weight-bearing.”

Professor Schuetz said this type of fracture was often caused by high-energy trauma such as car accidents in young people and falls in older people.

“Particular distal femur fractures in the elderly are increasing including fractures around knee replacements,” he said.

Professor Schuetz said the currently used standard locked plate constructs, which are screwed to the bone, assisted bone healing but can be often overly stiff and does not allow for sufficient movement for fracture healing.

“Concerns over implant breakages has led trauma and orthopaedic surgeons to be conservative when permitting patients to bear weight after the surgery,” Professor Schuetz said.

“Consequently, patients have reduced mobility and it takes up to 12 weeks or longer before they can resume normal daily activities.

“The biphasic plate is novel because it is designed to provide suitable flexibility for healing and increased implant strength to support early, full weight-bearing.

“It is an innovation that could be expanded to healing of other long bone fractures that are suitable for plating. In other words, the biphasic design has the potential to be the next step in fracture fixation.”

The project has received financial support from the AO Development Incubator.

Biphasic plating improves the mechanical performance of locked plating for distal femur fractures was published in the Journal of Biomechanics.

Media contact:

Rod Chester, QUT Media, 07 3138 9449, rod.chester@qut.edu.au

After hours: 0407 585 901, media@qut.edu.au